Individual solutions for mechanical engineering / OEM

Hot-melt adhesives and application technology from a single source

We are aware that every project in the area of special machine manufacturing is unique and brings with it individual challenges. As an experienced partner for hot-melt adhesives and application equipment, we specialise in developing tailor-made solutions that are designed precisely to the technical requirements of your machine projects.

Understanding of mechanical engineering: Our deep roots in the mechanical engineering industry and our own company history enable us to have a profound understanding of mechanical engineering. We use this knowledge to develop solutions tailored to your specific needs.

We cordially invite you to consider BÜHNEN as your partner for hot-melt adhesives and equipment for mechanical engineering. Together we can master the challenges of your projects and develop innovative solutions that will delight your customers.

Our offer for mechanical engineering

Your personal contact

We know the importance of direct communication. That’s why we offer you a contact person both on site and at our headquarters. Our team is always available to answer your questions and meet your requirements.

Customer Hotline: +49 421 5120-0

On-site service for your customers

Our qualified service team is available to you for commissioning and to your customer for subsequent maintenance and repairs of the machines. Whether on site or at our headquarters in Bremen – we are there for you and your customers to ensure that your machines run smoothly and efficiently.

Hotline: +49 421 5120-253

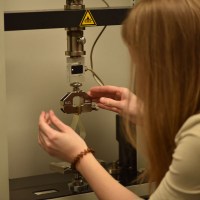

In-house laboratory

In our in-house laboratory we simulate the conditions of your (customer) applications to ensure that the selected adhesives and application techniques meet the highest standards.

HB 6000 series

The latest generation of the HB 6000 series of piston pump tank systems now offers a touchscreen for faster operation. Suitable for EVA, PO and PSA hot-melt adhesives.

Equipped with

- 7″ touchscreen for intuitive operation

- New options for integration into an existing periphery

- Highest compatibility with Nordson and Robatech

HB 4000 series

The HB 4000 connect melters can be precisely tailored to the individual requirements of the most diverse production areas. The solution based on the modular principle impresses with its efficiency and cost-effectiveness. Proven industrial electronics from Lenze, Siemens, Festo and Weidmüller are installed in this series.

- Pressure sensor as standard

- Dosing meter function (g/m - g/sec - g/m²)

- Weekly time switch

avenia packaging adhesives

These are particularly suitable for bonding in the packaging industry on high-speed machines where high restoring forces must be safety absorbed, such as trays and crates.

- Fast, immediate absorption of high restoring forces with a short pressure time

- Good free-flowing properties

- Optimised handling thanks to 15 kg bags