Selection of hot-melt adhesives for the concrete industry…/HU)

The use of hot melt adhesives in the concrete industry has considerably optimised the production process. Components for recesses in prefabricated components (e.g. for sockets) can be fixed to the formwork quickly and easily and can be removed again without leaving any residue once the concrete part has been completed. There is no need to use magnets or adhesive tape.

With the usage of hot melt adhesives in the concrete industry the manufacturing process could be optimized:

- Reduced time consumption in fast and secure fixing of components on the steel formwork (e.g. plastic or styrofoam spacer)

- Parts can easily be removed from the formwork without residues

- Quick and safe application without using magnets or adhesive tape

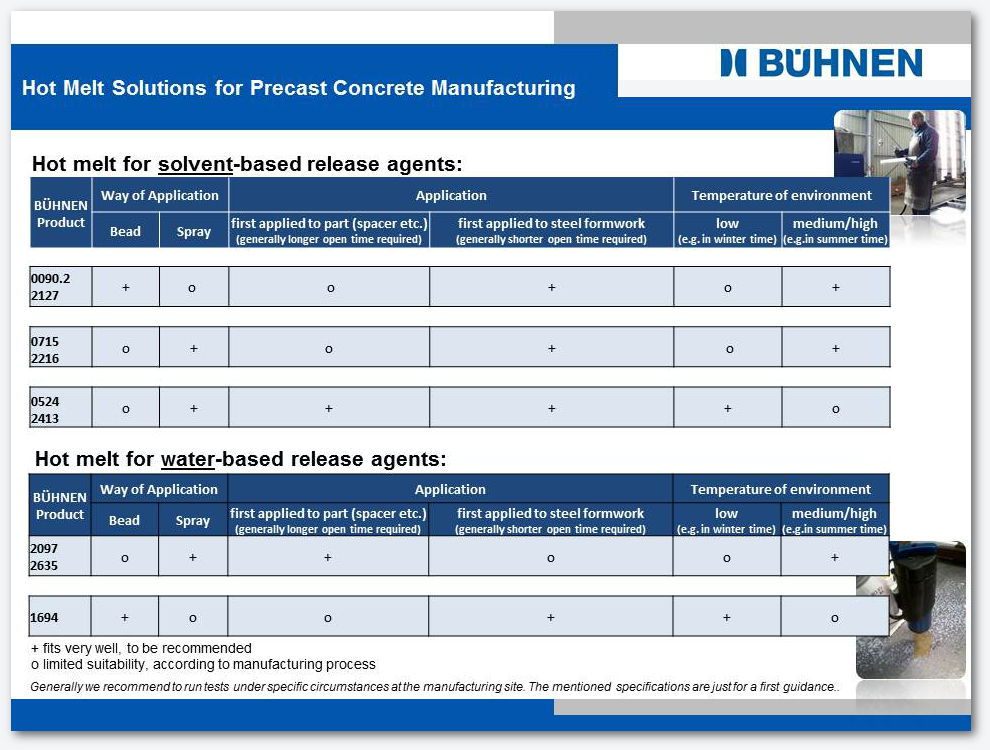

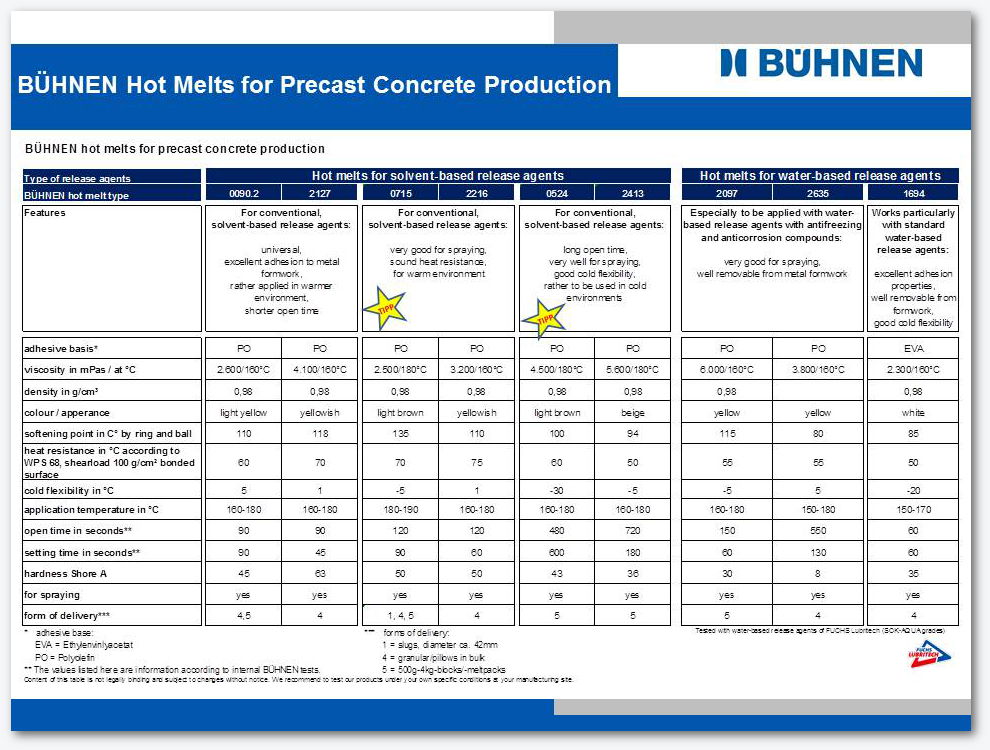

…for solvent-based, conventional form oils:

- Universally applicable with particularly low flexural strength when cold: 0090.2

- In a very cold environment (very good flexural strength), very good spraying properties: 0524

- In a rather warm environment (good thermal resistance), easy to spray:0715

…for water-based film oils:

each with good spray capability and particularly low flexural strength when cold:

- for water-based without frost and corrosion protection: 1694

- for water-based with frost and corrosion protection: 2097

click to enlarge

Hot-melt adhesives for the application of water-based film oils (emulsions):

- A variety of influential factors must be taken into account when using water-based film oils because of the widely known difficulty in bonding to water.

Optimum production conditions for the use of water-based film oils:

- Spraying the form release agent after application of components on the metallic sheet

For the form release application before applying the components:

- Sufficient flash-off time before the adhesive sticks to the releasing agent (guide value approximately 8-10 minutes)

- Wipe away any release agent residue before applying the component to the metallic plate

- Bead application with a bead thickness of approximately 5-6 mm

- Hall temperature approximately 18°C - 20°C

- Temperature of the metallic plate before the release agent is applied approximately 35°C - 40°C

click to enlarge

NB:

The release agent should be sufficiently exhausted of air until contact with the hot-melt adhesive. This is supported by a warm metallic plate and an adequate hall temperature. Applying a bead as opposed to a spray application contributes to improved evaporation of the water in the release agent thanks to the higher adhesive force in the bead.