PA Hot Melt Adhesives

PA Hot-melt adhesives

Glue safely and reliably with polyamide

Polyamides complete our range of hot-melt adhesives. The applications in which our adhesives are used could not be more different.

For example, our adhesives are true specialists in the field of glazed or varnished concrete or slate roof tiles.

Then again, others are used in the low-pressure injection moulding of electrical components. They score here with excellent flexibility at low temperatures and good plasticizer resistance.

In the automotive sector, PA hot melts are used in the foundry industry to manufacture cores using the Cold-Box or Hot-Box process.

How can you glue with our polyamides?

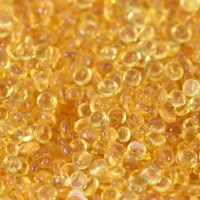

This is where you benefit from the wide range of application technology products. You can obtain polyamide from us as granulate and to some extent also in stick form. You can obtain both forms of the required application technology from BÜHNEN. Benefit not only from our knowledge of polyamide hot-melt adhesives, but also from the technical advice regarding application technology.

Advantages of polyamide / PA hot-melt adhesive

![]() Very high heat resistance

Very high heat resistance

![]() Excellent cold flexibility

Excellent cold flexibility

![]() more than 50% produced from renewable raw materials

more than 50% produced from renewable raw materials

![]() To some extent resistant to oils and chemicals

To some extent resistant to oils and chemicals

![]() To some extent with flame-retarding properties

To some extent with flame-retarding properties

Polyamide adhesive C0874 / C0874S

Low pressure injection moulding of electrical components and plug forms. Securing of electrical components on printed circuit boards, as well as enamelled wires on spools. Also available in black.

- Sticks and granules in two colours

- Good thermal stability and elasticity

- Good adhesion on soft PVC

- Excellent cold stability (down to -30 °C)

Polyamide adhesive C1404

For use in the roof tile industry as spacer or scratch protection for clay roof tile surfaces that are glazed or varnished

- Scratch protection

- Short setting time

- High blocking resistance

Polyamide adhesive C1429.2

For use in the roof tile industry as spacer or scratch protection for concrete roof tiles with anti-soiling coating, glazing or varnish on the upper side of the tile.

- Short open time

- Very short setting time

- High blocking resistance

Polyamide adhesive C2417

Very suitable for core bonding in the foundry industry and is also used in wood processing. It has a high initial strength.

- For cores manufactured using the Cold-Box / Hot-Box process.

- Especially for iron foundries

- For core packages to be coated (aqueous)

- Short open and setting times