News

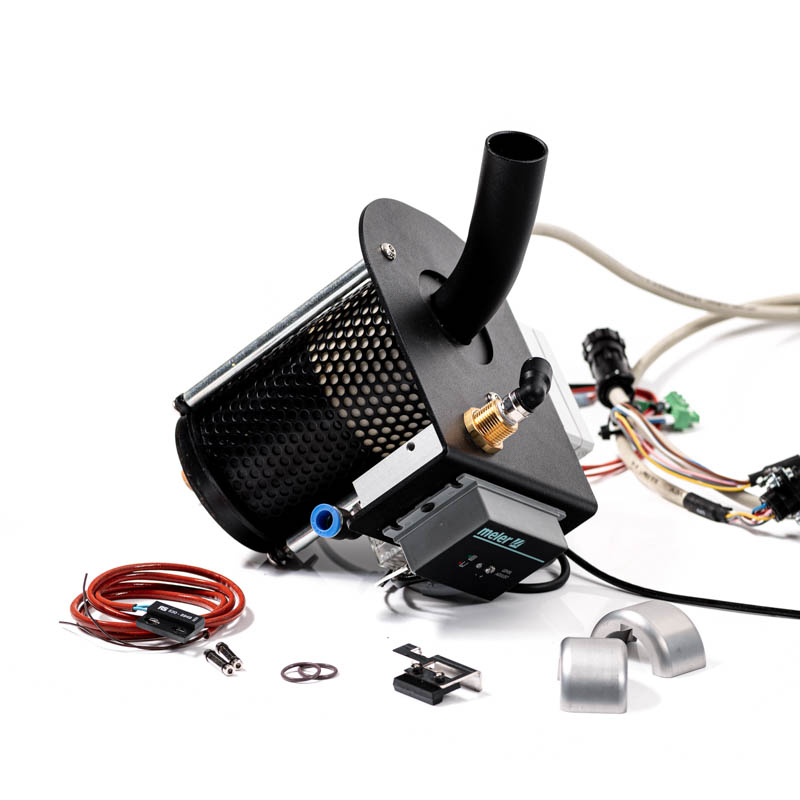

Granulate Feeders – Why is retrofitting worthwhile?

Sustainability begins with preservation

Every new investment means additional material consumption, disposal of old equipment and a change. With our retrofit kit you avoid all that: You extend the service life of your existing melting devices, reduce waste and rely on resource-saving optimisation.

Less manual intervention – more efficiency

Instead of manually refilling granulate, the retrofit kit with the granulate feeder takes over this task automatically. This not only means a significant time saving, but also a consistent supply of granules - without wastage or loss of material: Your existing equipment operates more efficiently. In addition, the closed system ensures that personnel costs for operation and the risk of injury to employees are reduced.

Homeease - Switching to BÜHNEN made easy

Welcome to BÜHNEN – your alternative to Homeease

Homeease is closing? No problem!

We offer you the right hot glue guns as an alternative. Our high-quality devices are the perfect solution to keep your business or shop running without interruption.

Why BÜHNEN?

- Quality and reliability: German engineering for maximum durability and efficiency.

- Wide product range: We offer replacements for all common Homeease models.

- Individual service: Personal advice, training and fast shipping.

Switching from Homeease made easy

- Free advice: Our experts will help you find the perfect solution.

- Test without risk: Request a test device and see for yourself yourself.

- Attractive offers for retailers

We support you

Whether packaging, crafts or creative applications - our hot glue guns stand for quality and reliability.

Contact us

Get advice now without obligation and discover how BÜHNEN meets your requirements.

Hotline:+49 (0) 421 51 20 0

E-Mail:info@buehnen.de

Find your suitable alternative to Homeease

HB 181

Alternative to G766 | G250 | K-600 | PT40

PT-80 | 1040A | 1060 | TE-508 | TE-808

- small and handy

- fixed nozzle (diameter 2.5 mm)

- available in a box

HB 191

Alternative to K-600S | K-1000 | G-250W

PT-100 | TE-9112

- Low weight

- High melting performance

- Nozzle can be changed (standard diameter 3.0 mm)

- Supplied in a case

HB 196

Alternative to K-1200 | PT-180 | TE-9112

- Removable plug for cordless operation

- Integrated on/off switch (illuminated)

- Nozzle can be changed (standard diameter 3.0 mm)

- Available in a box or case

HB 225

Alternative to K-2250 | PT-220 | PT-250

HB-200 | TE-9212

- Intuitive LED status display

- Removable cable

- Nozzle can be changed

- Adjustable temperature 140 - 230 °C

HB 240

Alternative to K-2200 | PT-350 | HB-350 | TE-9312

- 30% reduced trigger forces for fatigue-free work

- Precise, electronic temperature control

- Integrated on/off switch (illuminated)

- Nozzle can be changed (standard diameter 3.0 mm)

HB 250

Alternative to K-3350 | HK-612 | PT-412

HB-712 | TE-9412

- 30% reduced trigger forces for fatigue-free work

- Precise, electronic temperature control

- Integrated on/off switch (illuminated)

- Nozzle can be changed (standard diameter 3.0 mm)

HB 326

Alternative to HK-618 | PT-418 | HB-718| TE-9618

- For 18 mm sticks

- Very high melting performance

- Digital status display and settings

- 30% reduced trigger forces

- Mechanical stroke limitation

Frequently asked questions (FAQ)

1. Why should I switch from Homeease to BÜHNEN?

Our hot glue guns offer equivalent or better quality and are optimally tailored to industrial requirements.

2. Can I continue to use my existing adhesives?

Yes, our devices are compatible with a variety of adhesives compatible.

3. How quickly can I receive a device?

Thanks to our large warehouse and fast shipping, usually within a few days.

Everything will be different – only the price will remain the same!

When the new software for the relaunch of the HB 4000 was developed, the specialists from our product management team and the experts at SM Klebetechnik pooled their ideas and application knowledge.

The result is now available from us with the HB 4000 connect. The system series comes in a new colour guise, but the outward change is nothing compared to the revised range of functions:

The “connect” series has a large 7” colour touch display. This can be used to intuitively operate the clearly understandable menu structure. The software is included as standard in the entire device series.

Refurbished by BÜHNEN

The term refurbished is more familiar with regard to smartphones, tablets or laptops. Until now, the term has been less associated with industrial technology.

The issues of sustainability and climate change affect us all equally. When it comes to our products and work processes, employees are sensitized to look for more sustainable solutions.

In the case of nature bio based hot-melt adhesives, the product range has been expanded to include more sustainable products. On the technology side, we are now following suit with “refurbished by BÜHNEN”.

This is hot-melt adhesive technology that has been refurbished by our service professionals.

Is photography your passion?

Do you like to be out and about with your camera, and would you like to help shape the BÜHNEN family calendar 2024 and win a great surprise package?

Send us your motif (in printable resolution) by June 7th, 2023 to Heike.lau@buehnen.de. Please add a small profile to the photo with a few details about yourself and a short history of how the photo came about.