The swivel application head – a flexible solution

Swivel application heads are used in automated processes. The special feature of this design is the flexible suspension of the modules on the base body.

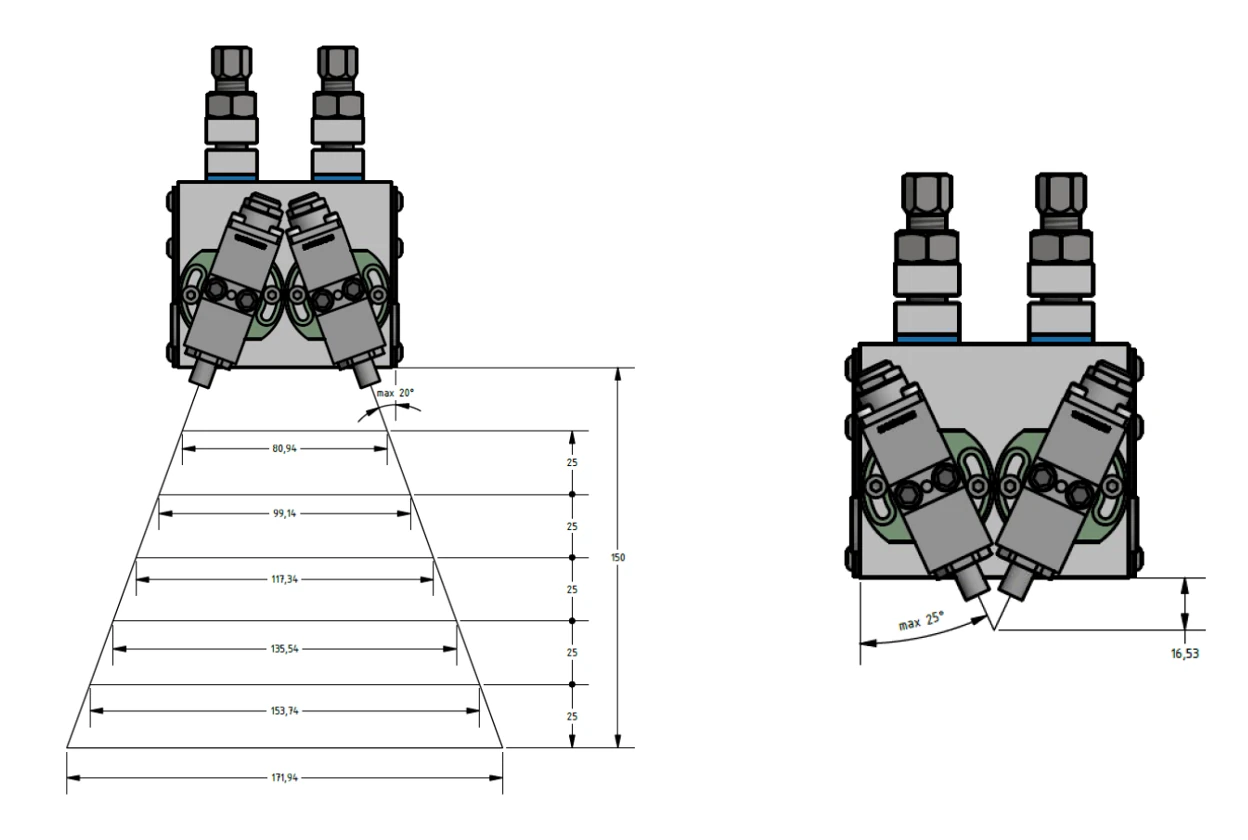

Construction of a swivel application head

In conventional application head designs, the modules are firmly connected to the base body. If there are several modules, these have a fixed distance from nozzle tip to nozzle tip in order to enable adhesive application at a constant distance.

Swivel application heads have rotating modules so that the nozzle tip distance can be individually adjusted.

Each of the two modules can be individually controlled by means of solenoid valves.

Swivel heads in small series production

The use of swivel heads is particularly recommended for small series production. The production line can be adapted to new conditions with minimal effort. The rotation of the module enables bead spacings of a few millimetres to several centimetres.

Swivel heads for special applications

Application heads with several permanently mounted modules are available in standard spacings, for example 22 or 68 mm. Swivel heads are a flexible solution to enable infinitely variable spacings without having to design a special application head.