Just carry out a simple test. light a candle and hold it at a roller shutter housing. Does the candle flicker?

Just carry out a simple test. light a candle and hold it at a roller shutter housing. Does the candle flicker?

If it does you can be sure the housing is not seal-tight - your expensive heat escapes outside. A roller shutter housing insulation can prevent this.

The most professional way to find thermal bridges in the house is to use a thermal imaging camera. This "thermography" can be carried out, for example, by an energy consultant. The images of this analysis normally show all too well where warmth is being lost in the home.

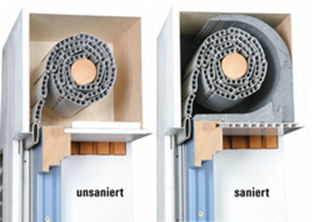

Up to the start of the 1990s, roller shutter housings had been made of thin pine wood. The housings – without effective insulation – were usually just plastered on the outer façade. And many of these still exist today. Rooms heated in this way resulted in the heat simply "evaporating" to the outside.

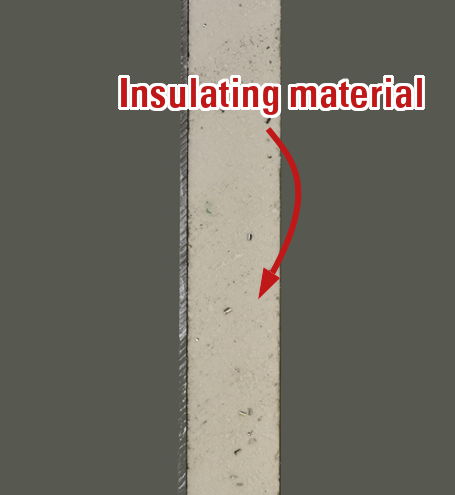

That is why modernization should include not only replacement of the windows but also of the roller shutter housings with efficient, insulated types. Used here as insulation material is either styrofoam or foamed plastic normally bonded with hot-melt adhesives. Bonding is mainly done onto a plastic or metal covering strip of the roller shutter housing.

In winter, the installed, insulated roller shutter stops the cold coming in. In summer, it shields the interior from the outside heat. As such, the hot melt adhesive is subject to marked differences in temperature throughout the year. Our customers have had very good results from the polyolefin-based B1063.1 hot melt adhesive type. It has both a high temperature stability and effective flexibility at low temperatures.

The application of the hot-melt adhesive is always matched to the respective manufacturing conditions. HB 910, for instance, has performed well given that insulation materials are usually bonded by hand in roller shutter housings. This hand gun is available in a spray and bead version. The hand-operated application device is an enclosed system given its connection via a hot melt hose to a HB 5010 type hot-melt adhesive tank.

Bonding involves the covering strip being applied with a number of hot-melt glue beads or being sprayed upon. The insulation material is then pressed on.

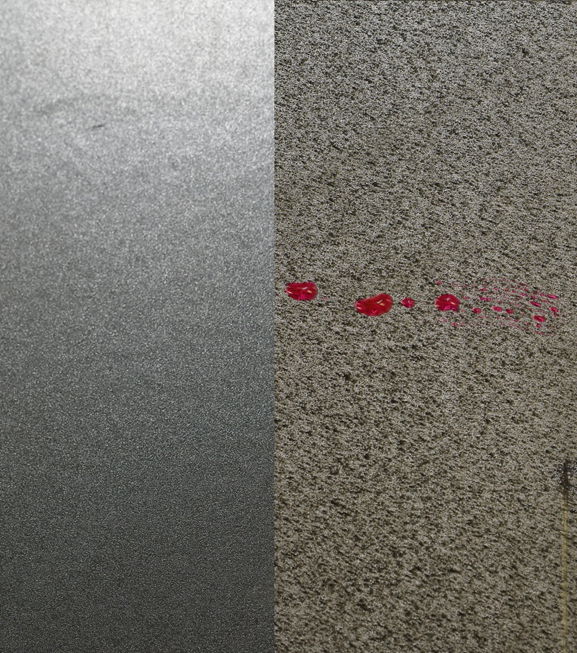

The shells of roller shutter housing are frequently powder-coated. The coating is of a particular colour and raises resistance to any damage from the elements. However, any kind of coating changes surface tension. Powder coating produces a low surface tension. But the lower the surface tension, the better do rain water and other contaminants run off. This is a thoroughly desired property for the exposed outer side of the roller shutter housing.

But in terms of effective bonding, a low surface tension inside the housing is counterproductive. What durable bonding needs for a sufficient wetting is an appropriate adhesive and a preferably high surface tension.

For this reason, the back of the roller shutter shell to be bonded should be masked, for instance, with adhesive tape before powder coating. The masking is removed afterwards. Alternatively, a surface treatment of the glued surface can be undertaken to raise surface tension at this point.