Bead nozzles

Bevel nozzle, tubular nozzle, nozzle bevel with capillary tube, round tube nozzle, flat tube nozzle, bead nozzle – there are many different names.But basically the same thing happens with all bead nozzles - an adhesive bead is shaped. That is, in principle, the case although things are far more diverse in practice.

All hand-operated devices and application heads require a nozzle for discharging or applying the adhesive. The application, hot-melt adhesive used and the application type determine which nozzle is selected.

Nozzle design

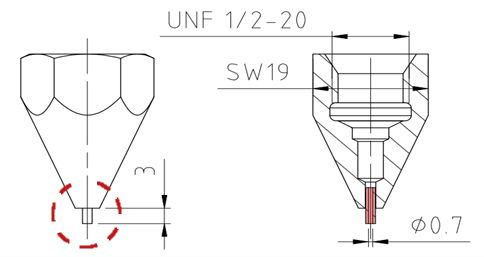

The nozzle is tapered towards the orifice resulting usually in a conical form. An inner and outer diameter of a nozzle opening is indicated. The inner diameter determines the discharging quantity of the hot-melt adhesive.Guiding principle: small diameter – less adhesive, large diameter – more adhesive.

A 3.0 mm diameter is considered to be large.

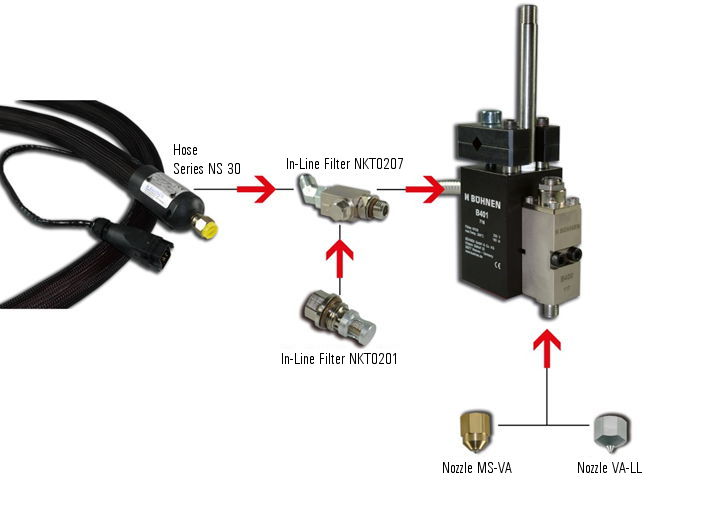

Such small diameters necessitate the nozzle also having an upstream filter to reduce the clogging risk. A top filter or a bag filter can be fitted for protective purposes.

Example for the set-up with filter sieve In-Line Series B 100Mesh

Some nozzle models have a capillary element for improved separation of the hot-melt adhesive. Capillary tubes are tubes with a small diameter and a thin wall.

Nozzle cone with capillary tube for pneumatic hot-melt adhesive guns

The thinner the wall, the better the fibre separation.

A number of models are fitted with a collar to protect the capillary tubes and nozzle tip.

Materials: Brass and stainless steel

Steel, stainless steel, aluminium and brass are used in manufacturing nozzles. Steel, aluminium and copper substances all have their advantages as well as disadvantages.Example: Brass is a gold-coloured alloy of copper and zinc. Different mixing proportions cause the brass to vary in colour from gold-orange to light-yellow.

Brass is very much a nozzle material in view of its excellent 120 watt (W/(m*K) heat conductivity. This permits an adequate temperature for the adhesive application to be obtained. However, brass is not resistant to wear due, for instance, to being relatively soft. As such, these nozzles are mainly used with hand-operated devices and stick guns.

Stainless steel is harder than brass and, consequently, stronger. Its 15 watt (W/(m*K) heat conductivity is comparatively low. Poor conductivity is therefore the reason why nozzles made of this material are shorter than brass nozzles. Stainless steel nozzles are often fitted together with application heads. As an insulation material, a number of nozzle variants have silicon sheaths fitted onto the stainless steel structure.

Nozzle wear

Nozzles are wear parts. For precision application, they should be regularly cleaned of adhesive residues. The nozzle needs to be replaced when, for instance, the bead from the application head is no longer straight.Hot-melt adhesive "scouring" causes wear to arise at the inner hole. From outside the nozzle is subject to abrasion from contact with the materials. Paper and cardboard, for instance, act like emery paper on the nozzle edges.

Even the preferred direction of application is recognizable from wear induced by hand-operated guns coming into contact with the material after lengthy usage.

HB 220 bead nozzle - new |

HB 220 bead nozzle - obliquely ground down |