Shore hardness

The method for measuring Shore hardness was developed by Albert Ferdinand Shore, an American engineer. Shore developed his hardness testing method in the 1920s and patented it in 1929. It was originally developed for measuring the hardness of rubber and other elastic materials, but has since found wide application in various industries, including adhesives technology.

The measured value gives you a material parameter for thermoplastics and plastics. There are two main scales for Shore hardness testing: Shore A and Shore D. For hot-melt adhesives, Shore A hardness testing is generally used.

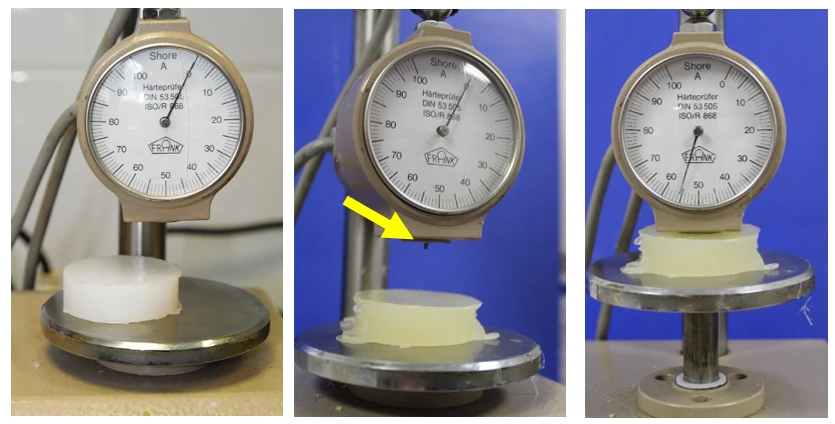

The measuring method with the durometer

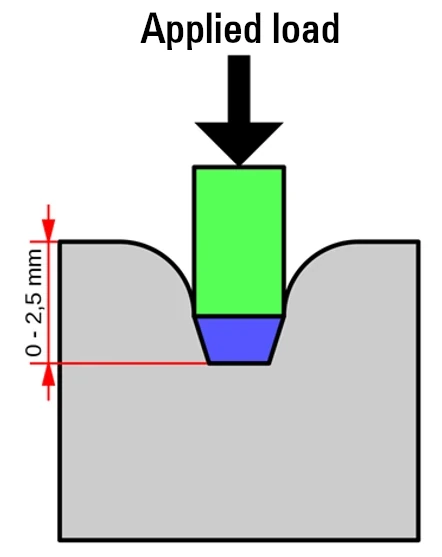

The Shore hardness tester’s measuring device essentially consists of a spring-loaded pin made of hardened steel.

Preparation of the material: The hot-melt adhesive is applied to a flat surface (in a test specimen) and allowed to cool and harden.

Measurement: The test specimen is pressed vertically onto the surface of the hot-melt adhesive until it reaches a defined penetration depth. This process usually takes a few seconds. The penetration depth is then measured.

Reading the hardness: This is measured on a scale from 0 Shore (2.5 millimetres penetration depth) to 100 Shore (0 millimetres penetration depth). The scale value 0 corresponds to the maximum possible penetration depth, i.e. the material offers no resistance to the pin being pressed in. On the other hand, the scale value 100 corresponds to a very high resistance of the adhesive to penetration and hardly any impression is produced.

Shore hardness testing is a quick and relatively simple procedure to characterise the hardness of hot-melt adhesives and to differentiate consistency between different batches or materials.

Adhesives with a higher Shore hardness are stiffer and less elastic, while those with a lower hardness are softer and more flexible.

Flee-flowing hot-melt adhesive granules, for example, have a relatively high Shore hardness. Adhesives used in the foam/upholstery industry have a low Shore value because the adhesive bonds must be flexible.

It is important to note that the Shore hardness is not a direct measurement of strength, but rather resistance to penetration. It can, therefore, only serve as an indirect indication of the strength and flexibility of the hot-melt adhesive.